Printing & Dying

Studying a Masters at UAL offers access to some fantastic resources including a print and dye room, which I have been taking advantage of.

Induction

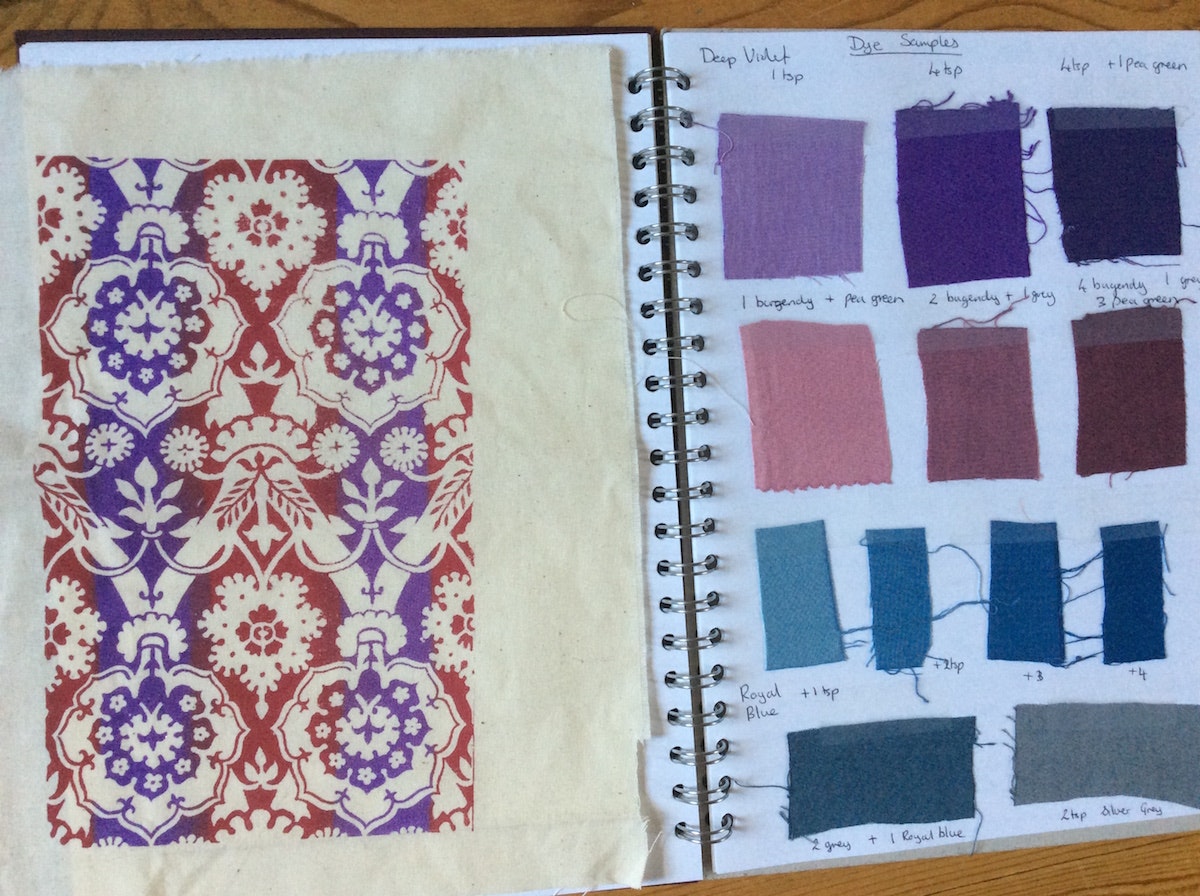

Before working independently in the Wimbledon dye shop it is essential to first complete a half day induction session. During this session we were introduced to the equipment, signing in protocols, health and safety and general working etiquette. We experimented practically with a range of techniques including fabric dying, colour mixing and screen printing. Samples were produced and annotated with useful notes for future reference. Having undertaken this enjoyable and useful session I was keen to undertake a project to incorporate these newly found skills and resources. This came quickly in the form of a costume as part of the Unit 1 the collaborative project.

Fabric dying for collaborative project costume:

1. A range of fabrics were selected for the costume including calico, cotton, lace and hessian to provide a palette of textures.

2. Colour samples were produced using direct dyes and appropriate base colours selected. Dip die techniques and layers were experimented with. All colours were mixed to form unique colours with slightly vintage hues.

3. Three dye vats were prepared with a dark blue/black, a purple/burgundy and a brown/gold.

4. The bulk fabrics were dyed each with a base colour and then dipped dyed into one or more other colours.

5. As a synthetic material the lace was dyed separately using a puple/black colour and ....dyes.

6. Dyed fabrics were washed and dried to be used in the construction of The Guardian Costume.

Please visit the collaborative project page, within the MA research section of my website for a full overview of this project.